5 Compartment Turnbuckle Trunking – W.Portsmouth Co. Ltd.

Spencer Yates2022-03-29T09:54:03+00:00Company: W. Portsmouth Co. Ltd | Location: Luton | Sector: Healthcare

At Tamlex we can turn around items from design to production, in a timely fashion to ensure we keep up to date with the requirements of this fast-paced industry, even in instances where bespoke products are required such as our 5-compartment turnbuckle trunking that was recently manufactured.

Luton & Dunstable Hospital were looking to update some of their archaic equipment as they begin building their state-of-the-art Energy Centre to support the hospital in becoming more environmentally friendly. The appointed electrical installation contractor, W. Portsmouth Co. Ltd. of Luton, chose Tamlex Steel Cable Management to provide the solution.

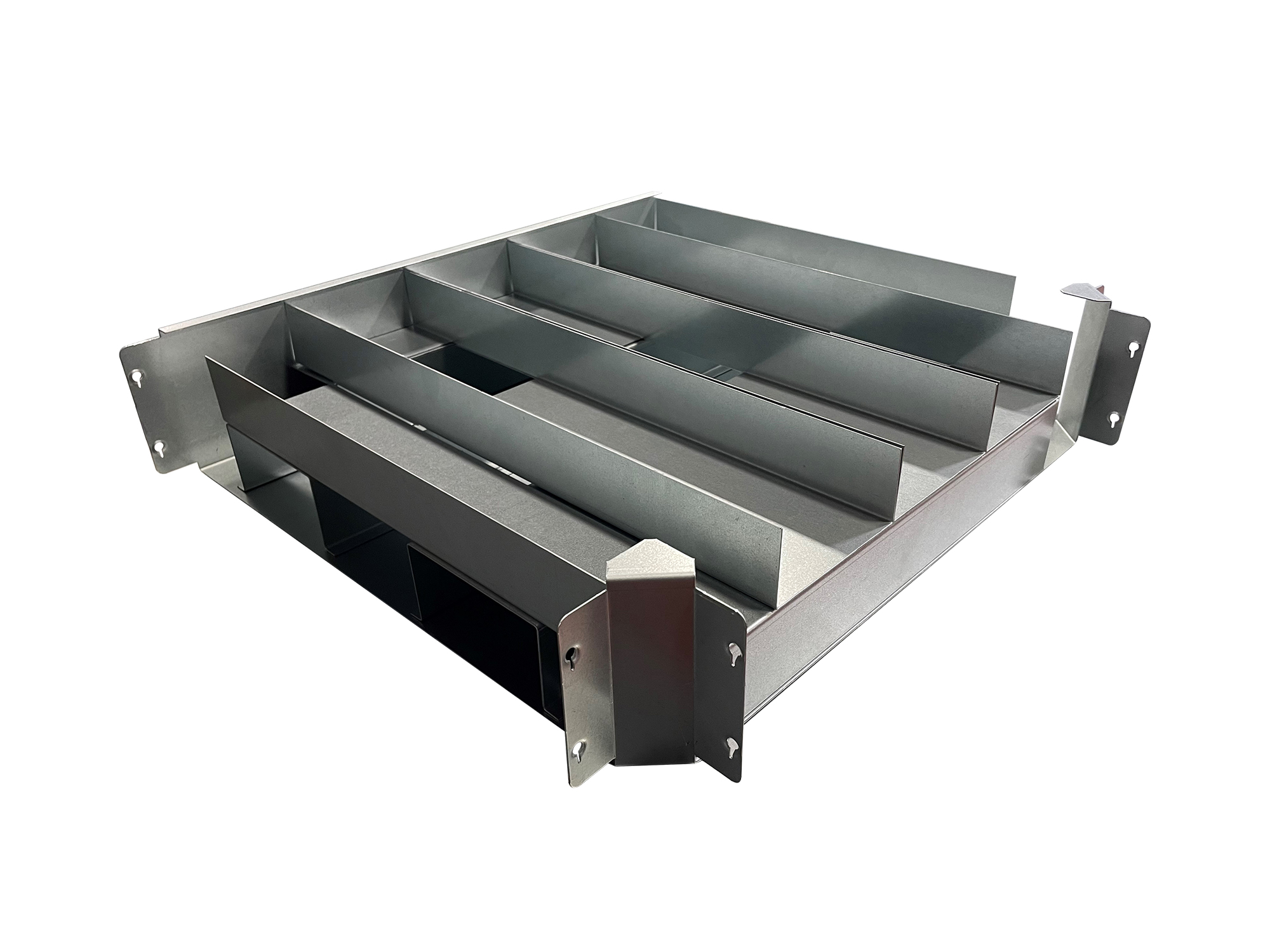

The hospital required varying sizes of turnbuckle trunking that incorporated 5 compartments. As a British manufacturer Tamlex have complete control over the production process and have the capability to design and manufacture specially fabricated products such as these.

Separate compartments enable the segregation of data and power cabling to avoid any electromagnetic interference with additional pathways for other services such as gas and air.

5 Compartment turnbuckle trunking products provided were:

- 258m 400mm x 100mm – 5 Compartment Turnbuckle Trunking

- 12m 300mm x 100mm – 5 Compartment Turnbuckle Trunking

- 141m 250mm x 100mm – 5 Compartment Turnbuckle Trunking

- Plus, all bends, tees and reduces to match

- 450mm Heavy Duty Cable Tray

- 225mm Heavy Duty Cable Tray

- Plus, all bends, tees and reduces to match

The products were designed in-house to fulfil all necessary requirements of the customer. Initial working samples were then made to ensure the products met the customer’s needs and worked efficiently in the finished environment.

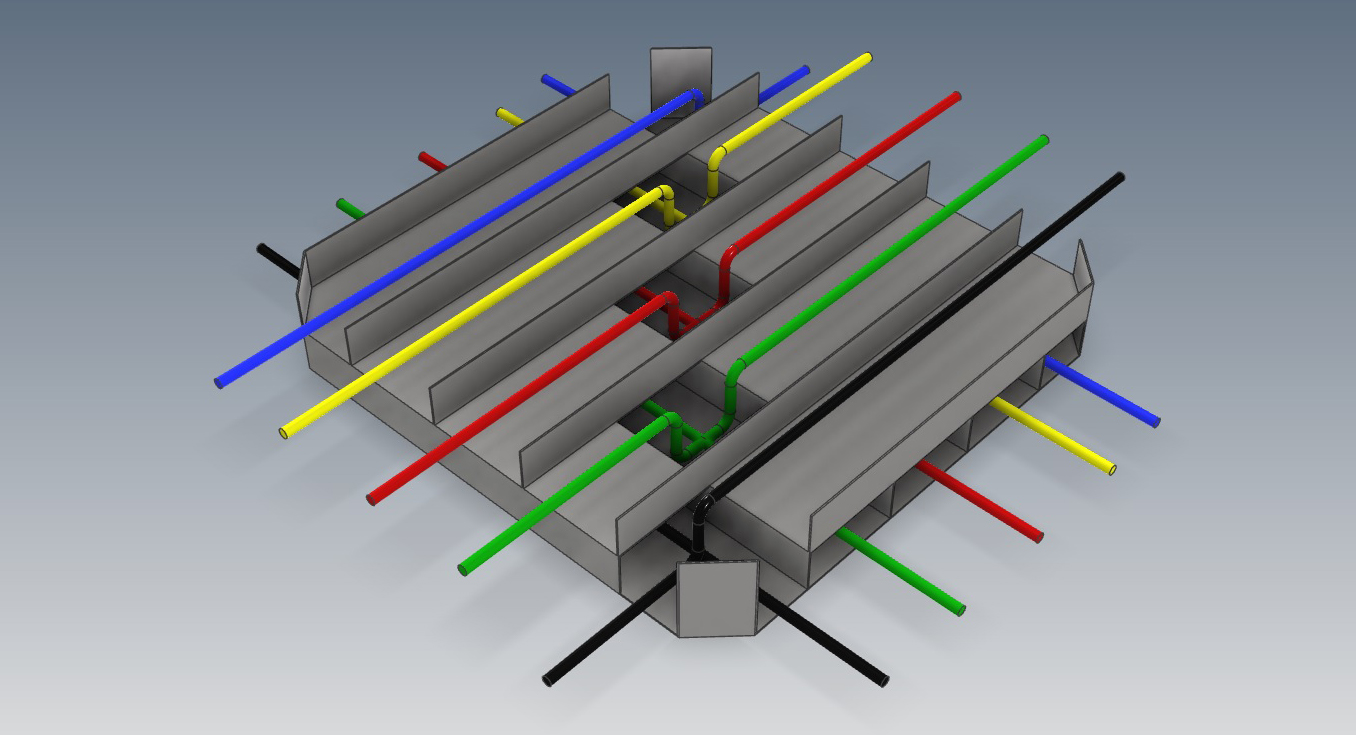

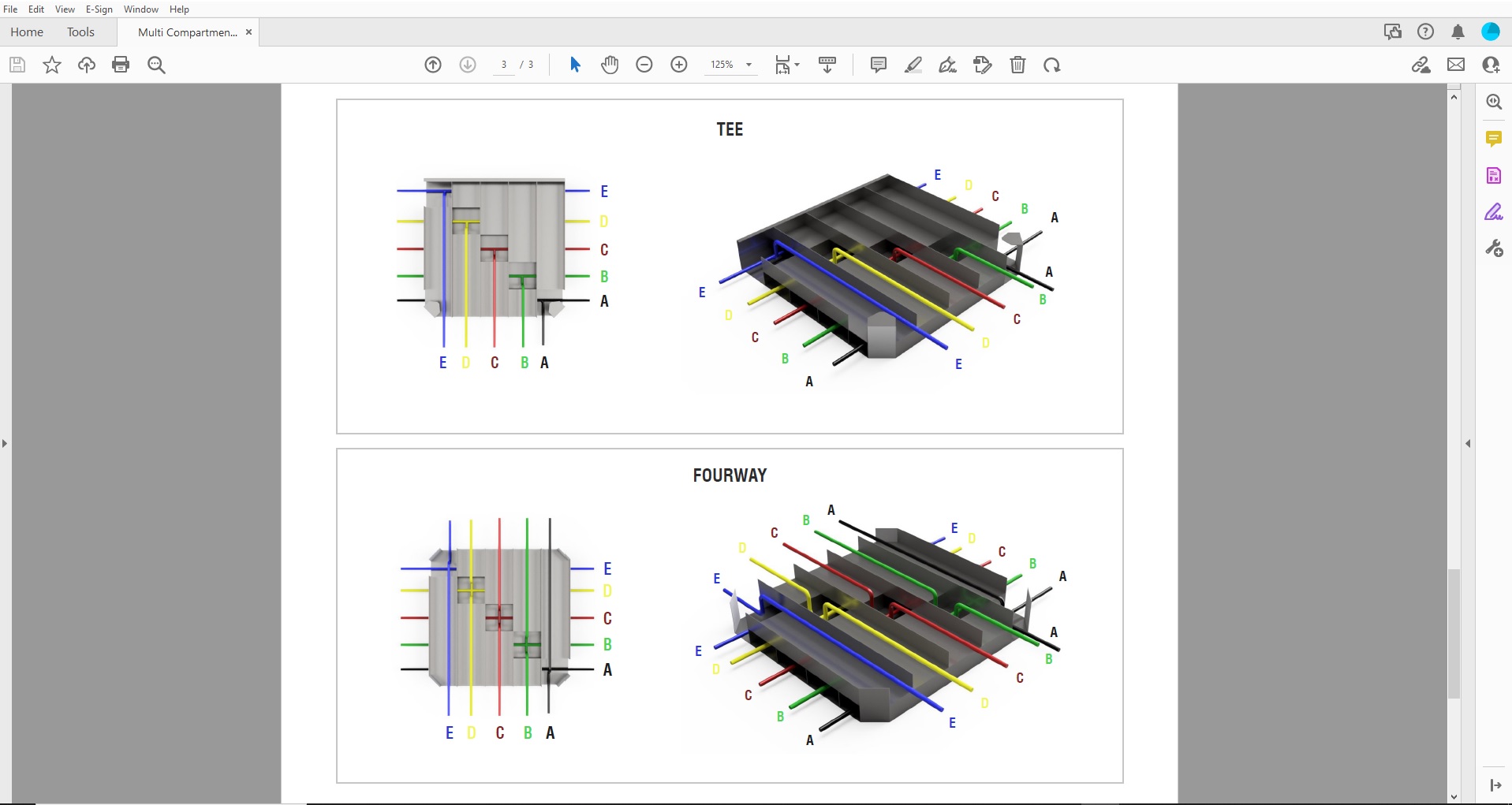

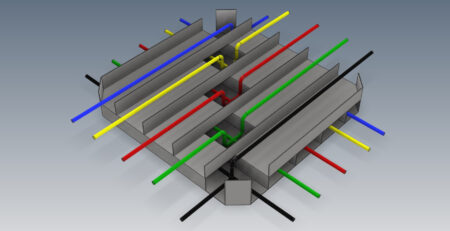

During this process, our customer requested clarification on how the cables would be installed into each of the 5 compartments. As a result, our in-house product designer was able to create visual representations of the final installation, depending on if it was a tee or four-way fitting. The 3D modelling software used to produce these visuals was Autodesk Inventor. Having these renders assisted in visualising how the product would look and to meet the customer’s requirements. Our extensive range of accessories to complement our turnbuckle trunking was something else that in this instance, fitted our customers’ demands to make these bespoke products effortless to install. All of which were custom designed and manufactured for this project.

This order of bespoke steel cable management was designed and manufactured in-house at our Telford based manufacturing facility. Working closely with our customers ensuring we were able to produce these products to their installation timeline and deliver direct to the site when required. Regular communication with the factory ensured this project ran smoothly and all parties were kept up to date with the progress.

For more information on our special fabrication services or to learn how we can add value to your steel cable management requirements contact the experienced Tamlex sales office: 01952 586689 or visit: www.tamlex.co.uk/special-fabrication/

Other Case Studies...

Steel Cable Management Installation at Evolution Foods’ Peanut Factory in Telford

Evolution Foods, a leading food processing company, embarked on a project to build a state-of-the-art peanut processing facility to meet... Read More

5 Compartment Turnbuckle Trunking – W.Portsmouth Co. Ltd.

Company: W. Portsmouth Co. Ltd | Location: Luton | Sector: Healthcare At Tamlex we can turn around items from design to... Read More

Steel Cable Tray – MHE (Halifax) Ltd

A.C. Entertainment Technologies Ltd. are a leading provider of professional equipment and related services to the entertainment industry supplying to... Read More

Wire Basket Tray – Ridgeons

Following a site visit where the choice of whether to use traditional steel cable tray for all the overhead containment... Read More