Zinc Magnesium

What is Zinc Magnesium (ZM)?

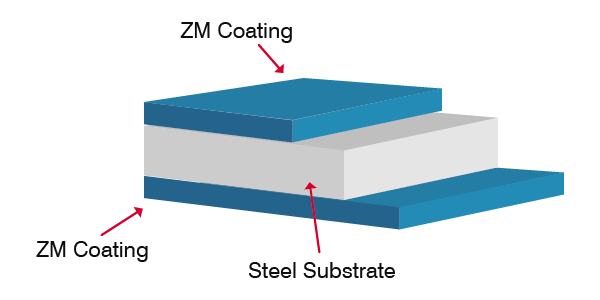

Zinc Magnesium (ZM) is a cutting-edge anti-corrosion coating that offers exceptional protection against corrosion. This innovative coating is a notable advancement over traditional Hot-Dip Galvanizing (HDG).

The ZM coating comprises 93.5% zinc, aluminium (3.5%) and magnesium (3%) formulated to create a corrosion-resistant, self-healing protective layer. Thanks to its 3% magnesium content, this protective layer is designed to withstand the harshest conditions, ensuring long-term performance, and making it a cost-effective solution.

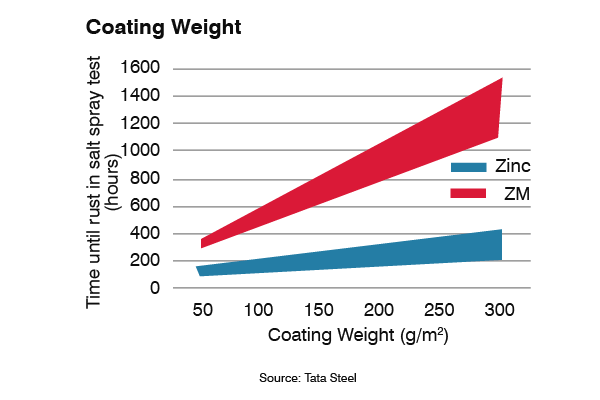

This high corrosion resistance means less metallic coating is required (weight reduction), which also facilitates processing steps such as welding.

Main Advantages:

Self-Healing Capability

Exceptional Corrosion Resistance

Lightweight Design for Easier Handling

Eco-Friendly & Sustainable

Long-Term Cost Efficiency

ZM Properties

The unique composition allows for better performance in harsh environments, making it ideal for various applications where durability is key.

Its ability to form a sturdy, long-lasting barrier under challenging conditions underscores its superiority over conventional zinc coatings, making it an invaluable material in industries like construction, data centres, automotive, and infrastructure that demand high-performance, long-lasting protective solutions.

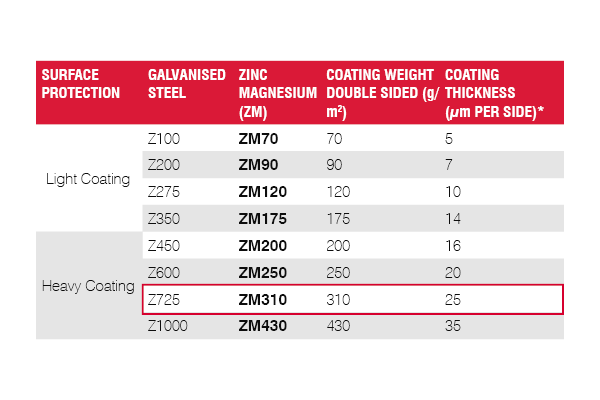

ZM Coating Weight and Typical Thickness

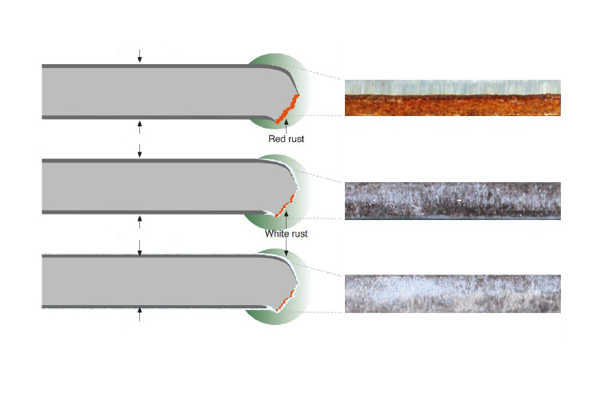

Self-Healing Effect

Initial exposure period (up to several weeks)The exposed cut end of the substrate is oxidised and forms red rust.

When subjected to rain and condensation (beyond several weeks *).

The zinc-based film containing the magnesium on the coating layer migrates over the cut end.

Long exposure period (after more than a year)

Disappearance of red rust and the increase of white rust.

The speed of the self-healing may depend on the environment.

Common Questions

- Zinc Magnesium (ZM) exhibits enhanced weldability due to its thinner coating.

- The welding processes employed for ZM are identical to those used for zinc-coated materials.

- Consistent welding consumables, procedures, and guidelines can be implemented.

- ZM provides superior corrosion resistance for re-protected welded areas compared to post-galvanised coatings.

- ZM supports powder coating applications effectively.

- It delivers exceptional corrosion resistance, surpassing that of other metallic-coated steels.

- Friction test results indicate that ZM outperforms hot dip galvanised steel.

- Steel components coated with ZM are easy to process without damaging tools.

- ZM allows for the deformation of steel without the application of lubricants.

Zinc Magnesium Brochure

Zinc Magnesium (ZM) is a state-of-the-art anti-corrosion coating that delivers superior protection against corrosion, representing a significant improvement over the conventional Hot-Dip Galvanising (HDG) method.

Its ability to form a sturdy, long-lasting barrier under challenging conditions underscores its superiority over conventional zinc coatings, making it an invaluable material in industries like construction, data centres, automotive, and infrastructure that demand high-performance, long-lasting protective solutions.

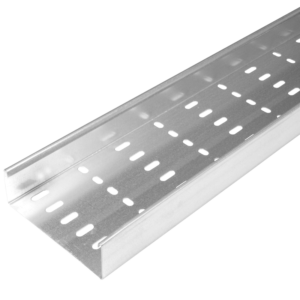

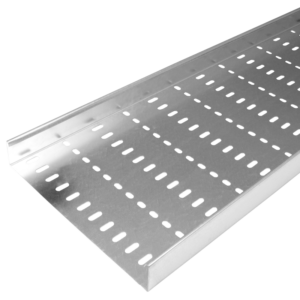

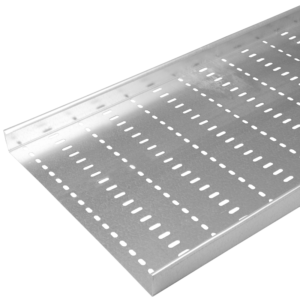

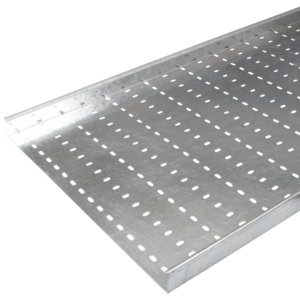

Zinc Magnesium Cable Tray

Tamlex Zinc Magnesium cable trays offer a robust and corrosion-resistant solution for cable management in both industrial and commercial environments. Their lightweight construction allows for easier handling and installation, while maintaining high load-bearing capacity. Ideal for indoor and outdoor use, Tamlex Zinc Magnesium cable trays ensure reliable performance and long service life, making them a cost-effective choice for modern electrical infrastructure.

Zinc Magnesium Strut

Tamlex Zinc Magnesium strut systems are designed to provide strong, reliable support for electrical and mechanical installations. Coated with a zinc-magnesium alloy, they offer exceptional corrosion resistance, making them ideal for use in demanding environments such as industrial facilities, plant rooms, and outdoor installations. The struts are compatible with a wide range of fittings and accessories, allowing for flexible configuration and easy installation. Combining durability, strength, and long-term performance, Tamlex Zinc Magnesium struts are a smart choice for modern support frameworks.